Interview with Joachim Fiedler - Founder of FIDLOCK

Music has a special role in your life and can also be seen as the starting point of your following entrepreneurship. Where do these genes originate from?

My parents would have loved to become musicians. However, they did not grow up in times of peace. My father has kept his violin safe during the war. My mother comes from a household of music teachers and would have loved to become an opera singer. This was later achieved by her daughter/my sister. The family Fiedler has always played music – be it with instruments or singing – and since my father is Baptist, we used to visit different Baptist chapels.

After I graduated from school, I studied cello and the inconvenient bow holder always got on my nerves. So, I have invented a magnetic holder and, additionally, a multi-functional seat cushion for the musician and a cello harness. This harness turned out to be my first patent.

So, you are not just a musician but an inventor as well. And how did you get the idea for the patents? After all, that isn’t a given.

I have always loved to do handicraft work or experiments and I always had ideas haunting my thoughts. My sisters still love telling the story of how, as a child, I sketched a combine harvester where the corn enters at the front, and ready-made jelly sandwiches come out at the end.

At my school graduation, I had three different career aspirations:

Making violins – I had already started carving wooden spirals for the qualifying examination of the luthier school.

Nuclear physicist – I voluntarily chose physics as an additional main subject in school and dozed off in bed, reading Weizsäcker and Heisenberg. To this day, I still find myself engaging in topics such as reactor design.

The third wish was cellist – I got a spot as one of the twelve students in the class of the world-famous cellist David Geringas. I finished my studies in Berlin and, afterwards, I worked as a musician, helping out at the Berlin Philharmonic and toured the world with multiple orchestras.

But you still became an inventor?

My former colleagues currently work as cellists in radio orchestras, professors, or solo artists. I am one of the few that drifted into other professions. I never let go of my cello bow holder. I thought I was the first to use the reverse polarity of magnets in a fastener. In specific, a fastener opened by a movement that brings the positive and negative poles together and, thereby, allows it not only to close but open automatically as well. However, this was already used for lightbulbs and refrigerator doors. I nonetheless found a very important feature which has lead to the second patent for the holder, after the first for the cello harness.

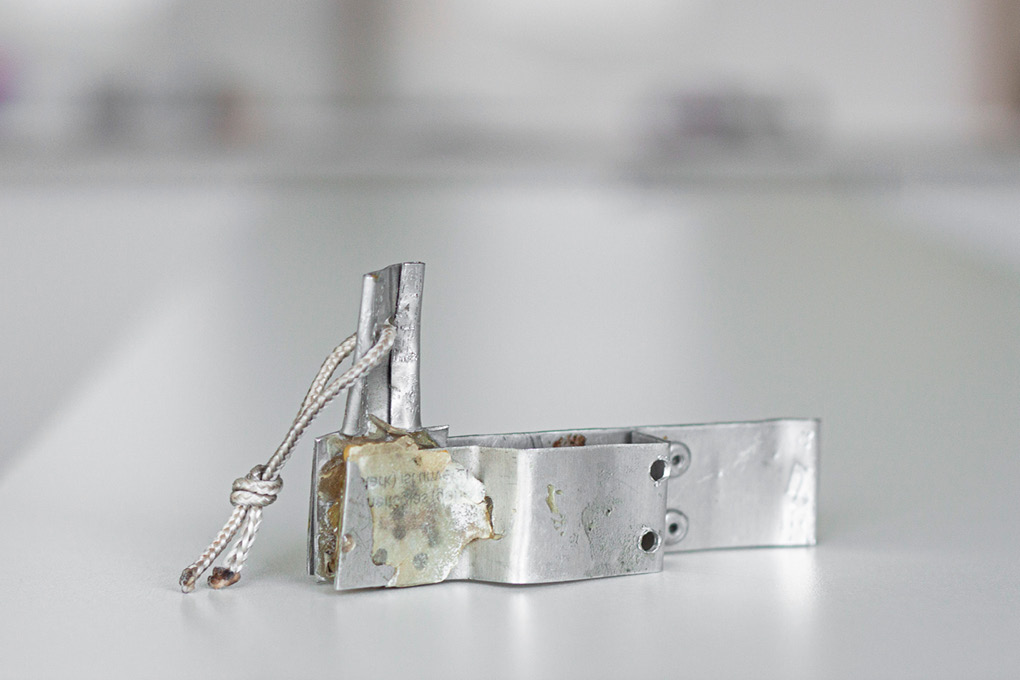

The first two pictures show the first prototype of the bow holder.

This is how the bow holder looks today.

And again, why patents?

I didn’t have the ideal patent lawyer for this technical field, so I wrote the first patents by myself (today I have a lawyer who knows my patents better than I do). This led to me looking into all the patents related to “magnetic fasteners”. It took me three weeks, from early in the morning to late at night – and in the end, I was certain that this is what I want to do. Therefore, the magnetic bow holder developed into a magnetic fastener for school bags.

Patents aren’t merely written to secure one's rights. Additionally, they force you to really take a detailed look at the subject, to work systematically, to define features, to vary, and to reassemble. Suddenly, something is created which you didn’t even have in mind. That is how you can achieve new inventions. I can only recommend it.

It played a large part in building the success of FIDLOCK. A part of our current portfolio consists of licenses - that require patents. They act as a huge deterrent. If someone wants to create a patented magnetic fastener, they have to read thousands of pages written by FIDLOCK to make sure that they don’t infringe any of our patents.

Of course, the first patents where mine, but today we have an unusually large development team. Almost a third of our 56 employees. The DNA transferred itself and my team is developing new patents, which is amazing. We apply for more every year.

How did you actually end up in Hanover?

My mother grew up in Göttingen and my father is from Landsberg an der Warthe (Poland) and went to Hessen in Germany after the war. I grew up in Kassel and then lived in Berlin for 20 years.

The financial crises brought me to Hannover. I started my first financing round in 2007 and thought 600.000 Euro would suffice. However, the money was used up far too quickly. So, I showed up and applied everywhere. Wolfgang Lubert from Enjoy Venture was (and still is) the manager of the “Hannover Beteiligungsfonds” and offered me the funding which required me to come to Hanover. So I did with my family, much to the dismay of my wife. As an architect, she still misses Berlin. Today, we and our two children (5 and 11 years old) enjoy the perks of Hanover, such as the boys' choir Hanover and the Eilenriede.

FIDLOCK started with a team of 5 in a backyard of the Prinzenstrasse, followed by an office in the Dragonerstraße, then the Hindenburg-quarter, and now the fourth residence in Hanover Lahe.

Why did you move Headquarters and why exactly this building? This used to be the office of the energy provider Eveen and before that, the new apostolic church's main office of northern Germany.

Correct. Our primary reason was the underground garage.

Why the garage?

We had a great office in our previous building in the Hindenburg-quarter. However, FIDLOCK grew very quickly – we had 40 employees in 2018, 50 in 2019, and today we are about 60 people. The space at the previous location was getting quite cramped. On top of that, we need a lot of space for storage and workshops in addition to bright and friendly office-rooms. This is given by the underground garage which made the new building our preferred choice. Most of us commute by bicycle. Therefore, we don’t need as many parking spaces and can use them for storage.

Where do you produce?

The magnetic fasteners and our water-proof dry bags are produced in China, because most of our principal customers, producing bags and footwear, are based there. Even if we could produce for the same cost here, it would not be possible to get the orders to them in time. Additionally, since we need to manufacture a lot according to customer preferences, we produce where the customer’s production is based.

Furthermore, FIDLOCK today only makes about a third of its turnover in Germany. China and the US are very large markets for us, but also Chile and Thailand. In total, we have 55 distributors and sales partners in 36 countries. However, my connection to China has started earlier. In 2008, I visited the country and, following a recommendation of a good friend, found an engineer who was also about to start his own business, giving our companies the ideal opportunity to grow together.

At the start of this year, we founded our subsidiary FIDLOCK Industrial (Shenzen) Limited. Unfortunately, I couldn’t visit our new Chinese office yet, due to the current travelling restrictions.

One last question: Are you playing the Cello, when you’re not busy thinking about magnetic fasteners?

Unfortunately, not so much at the moment. Currently, I think about the climate a lot. In these times we need to listen to scientists. Look at the blue ski without vapour trails(due to the travel restrictions in 2020). Alone the absence of sulphur emissions in heights can create the possibility of temperatures rising more than a degree. This is caused by the Global Dimming, the constant artificial volcanic eruption which we currently turned off. On the one hand, I need to run a business which needs plastic and neodymium for its production - on the other hand, I keep asking myself how I can make climate-friendly changes. Therefore, we have brought to life a task force at FIDLOCK and are turning to Atmosfair for consultation. The director is an old choir friend of mine.

*This interview was originally held in German and translated into English for international readers.